Bad Batches Are No Longer A Concern

Have you ever thrown away a bad batch due to bad formulas or missed steps in the process? What if we could guarantee that no longer happens. Automation is the best solution to preventing wasted money on bad batches. Carlton Industrial Automation provides unique custom batching systems that fit into your production, no matter how complex the operation.

We offer turn key custom batching systems in manual, semi-automatic, and fully automatic systems as well as software batching solutions through our data manager software.

-

BatchPlus! Manual

BatchPlus! Manual is your solution for manual batching processes where operators are always present. User prompting prevents addition of incorrect products in unapproved amounts through weight data and barcode scanning. With operators being lead through every step of the process, bad batches are eliminated.

Request More Info → -

BatchPlus! Semi-Auto

BatchPlus! Semi-Auto is your step into automated batching. With I/O control, feeder systems becomes automated by weight. User prompting through METTLER TOLEDO terminals in combination with barcode readers and user prompting ensures scales users do not miss a step or add inappropriate amounts of material.

Request More Info → -

BatchPlus! Fully Auto

BatchPlus! Fully Auto is your complete solution for automated batching. These solutions are ideal for full 24/7 operation with complete PLC control, ERP integration, and come in fully hazardous solutions.

Request More Info → -

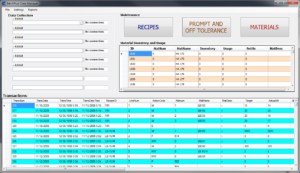

BatchPlus! Data Manager

BatchPlus! Data Manager allows advanced data management for BatchPlus! systems. Data Manager can handle centralized recipe editing to ensure that as your formulas change your system can easily keep up. Auditing becomes seamless with centralized track and trace functionality and lot tracking. Customizable reports show you the data you need to make impactful

Request More Info →